- DAN Feed: DAN Feed factory was established in 2008, together with Superdan Feed factory bonds together with the same aim of providing the finest quality of feed and premixes through a production capacity of 50 tons per hour in different sizes for a broad range of animals up to Today. The factory is now operating at full capacity and supplies most of the region’s farms with; broiler, layer, breeder, fish, and ruminant feeds. The professionality of our experienced staff during the last 14 years of experience has led DAN Feed & Superdan Feed to be the first and always the choice for a wide range of poultry, ruminant, and fish livestock. Moreover, the selection of a variety of raw materials is directed in a strict Quality Control environment in order to produce the best quality feed at a high standard.

- DAN PREMIX:

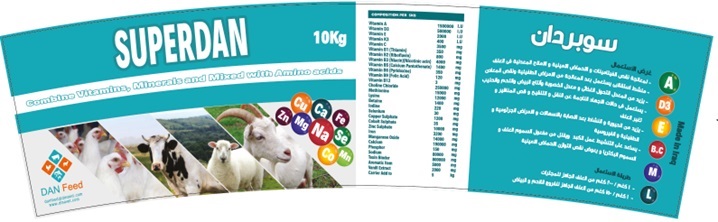

1- SuperDAN Premix is one of the most exceptional premixes we’ve ever produced at Dan Feed, which contains all vitamins, minerals, and amino acids at a high rate. What makes Superdan unique is the feed additives such as Toxin Binder that prevent the animal from being poisoned by molds that can be present in the feed. And other feed additives that enhance the animal’s performance, and the quality of its meat, milk, and eggs. SuperDAN is available in two weights: 5 KG and 10 KG

2- Calsporin from Calpis (U.S.A) is considered the most quality probiotic in the world among the others in the market. It’s imported by DMA Group, and permission has been granted to Dan Feed Factory in order to perform the dilution of the probiotics here in our factory under the supervision of Calpis.

- DAN Block: We use the necessary amount of minerals when making the mineral salt blocks in order to keep the animals away from the deficiency of minerals in their bodies. Other substances are also used that make the blocks more firm that can’t easily be pulled apart while being eaten by the animal.

- DAN Corn: Corns are bought from local agricultural farms and are brought to our laboratory; to analyze the corn for their moisture and mold rate. Afterward, it will be sent to the Heat Dry Milling process in order to de-moisturize it before being stored in our silos to be ready for use and sale to the market.

- Fish Project: The fish project consists of 7 fishponds divided on an area of 75,000 square meters, each 2,500 square meter contains 1,000 carb-type fish weighing 350 grams as initial weight until they grow up to 2.5 kg and then sold to the market, which takes 5 months per cycle. Moreover, Ecocid S which is a high-quality universal disinfectant is used for each 2,500 square meters once every week in order to provide a clean and healthy environment for fish.

The fish project is running according to water quality standards as mentioned below: